What are the Latest Ceramic Capacitors and Equipment Components Procurement Models?

I. Introduction

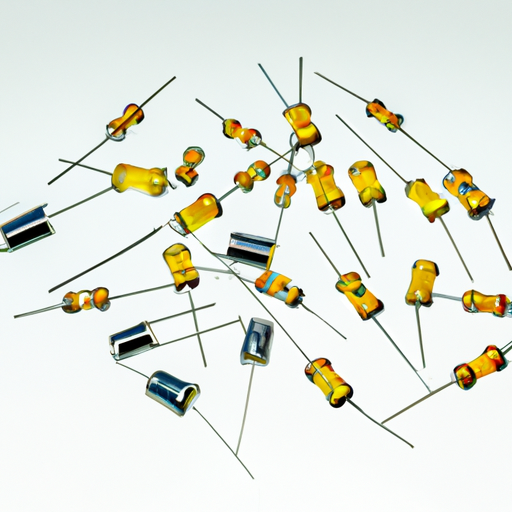

Ceramic capacitors are essential components in modern electronics, playing a critical role in various applications ranging from consumer electronics to automotive systems. These passive components store and release electrical energy, helping to stabilize voltage and power flow in circuits. As technology advances, the procurement models for these components are also evolving, reflecting changes in manufacturing processes, supply chain dynamics, and market demands. This blog post explores the latest trends in ceramic capacitors and the procurement models that are shaping the electronics industry.

II. Understanding Ceramic Capacitors

A. Types of Ceramic Capacitors

Ceramic capacitors are primarily categorized into two classes: Class 1 and Class 2 capacitors.

1. **Class 1 Capacitors**: These capacitors are known for their stability and low loss characteristics. They are typically used in applications requiring precise capacitance values, such as timing circuits and filters. The most common dielectric material used in Class 1 capacitors is NP0 (C0G), which offers excellent temperature stability.

2. **Class 2 Capacitors**: In contrast, Class 2 capacitors, such as X7R and Y5V, are designed for higher capacitance values but come with greater variations in capacitance with temperature and voltage. These capacitors are widely used in applications where size and capacitance are more critical than precision, such as decoupling and bypassing in power supply circuits.

B. Key Characteristics and Specifications

When selecting ceramic capacitors, several key characteristics must be considered:

1. **Capacitance Values**: Ceramic capacitors are available in a wide range of capacitance values, from picofarads (pF) to microfarads (µF), allowing for flexibility in design.

2. **Voltage Ratings**: The voltage rating indicates the maximum voltage the capacitor can handle without breaking down. It is crucial to select a capacitor with a voltage rating higher than the maximum voltage in the application.

3. **Temperature Coefficients**: The temperature coefficient affects how capacitance changes with temperature. Understanding these coefficients is vital for applications that operate in varying thermal environments.

C. Applications of Ceramic Capacitors

Ceramic capacitors find applications across various sectors:

1. **Consumer Electronics**: In devices like smartphones, tablets, and laptops, ceramic capacitors are used for decoupling, filtering, and energy storage.

2. **Automotive**: With the rise of electric vehicles and advanced driver-assistance systems (ADAS), ceramic capacitors are crucial for power management and signal processing.

3. **Industrial Applications**: In industrial machinery and automation, these capacitors help in power supply stabilization and noise reduction.

III. Trends in Ceramic Capacitor Technology

A. Advancements in Materials and Manufacturing Processes

Recent advancements in materials science have led to the development of high-k dielectrics, which allow for higher capacitance in smaller packages. This miniaturization trend is essential for meeting the demands of compact electronic devices.

B. Impact of Technology on Performance and Reliability

The integration of advanced manufacturing techniques, such as multilayer ceramic capacitors (MLCCs), has significantly improved the performance and reliability of ceramic capacitors. These capacitors can achieve higher capacitance values while maintaining low equivalent series resistance (ESR), which is critical for high-frequency applications.

C. Sustainability and Eco-Friendly Materials

As the electronics industry moves towards sustainability, manufacturers are exploring eco-friendly materials and processes. This shift not only addresses environmental concerns but also meets the growing demand for sustainable products from consumers and regulatory bodies.

IV. Procurement Models for Ceramic Capacitors

A. Traditional Procurement Models

1. **Direct Purchasing**: This model involves purchasing components directly from manufacturers or distributors. It is straightforward but may not always provide the best pricing or availability.

2. **Bulk Buying**: Companies often purchase large quantities of ceramic capacitors to benefit from volume discounts. However, this approach requires careful inventory management to avoid excess stock.

B. Modern Procurement Strategies

1. **Just-in-Time (JIT) Procurement**: JIT procurement minimizes inventory costs by ordering components only as needed. This model requires strong supplier relationships and reliable logistics.

2. **Vendor-Managed Inventory (VMI)**: In VMI, suppliers manage the inventory levels of their products at the buyer's location. This approach can enhance efficiency and reduce stockouts.

3. **E-Procurement Platforms**: The rise of digital platforms has transformed procurement processes, allowing companies to streamline purchasing, compare prices, and manage suppliers more effectively.

C. Collaborative Procurement Models

1. **Group Purchasing Organizations (GPOs)**: GPOs enable companies to pool their purchasing power to negotiate better prices and terms with suppliers.

2. **Strategic Partnerships with Suppliers**: Building long-term relationships with key suppliers can lead to improved pricing, reliability, and innovation in product offerings.

V. Factors Influencing Procurement Decisions

Several factors influence procurement decisions for ceramic capacitors:

A. Cost Considerations

Cost remains a primary factor in procurement decisions. Companies must balance the need for quality with budget constraints, often leading to negotiations with suppliers.

B. Quality and Reliability

The reliability of ceramic capacitors is paramount, especially in critical applications. Companies must assess supplier quality certifications and track records to ensure they are sourcing reliable components.

C. Lead Times and Supply Chain Dynamics

Lead times can significantly impact production schedules. Companies must consider the reliability of suppliers and their ability to meet demand fluctuations.

D. Supplier Relationships and Performance Metrics

Establishing strong relationships with suppliers can lead to better service and support. Companies often use performance metrics to evaluate supplier reliability, quality, and responsiveness.

VI. Challenges in Ceramic Capacitor Procurement

A. Supply Chain Disruptions

Recent global events have highlighted vulnerabilities in supply chains, leading to delays and shortages of critical components, including ceramic capacitors.

B. Fluctuating Raw Material Prices

The prices of raw materials used in ceramic capacitors can be volatile, impacting overall costs and procurement strategies.

C. Regulatory Compliance and Standards

Compliance with industry standards and regulations is essential for ensuring product safety and reliability. Companies must stay informed about changing regulations that may affect their procurement processes.

D. Technological Obsolescence

As technology evolves, older capacitor models may become obsolete, necessitating continuous monitoring of market trends and innovations.

VII. Future Directions in Procurement Models

A. Integration of AI and Machine Learning in Procurement

Artificial intelligence (AI) and machine learning are poised to revolutionize procurement by enabling predictive analytics, optimizing inventory management, and enhancing supplier selection processes.

B. Blockchain Technology for Transparency and Traceability

Blockchain technology can improve transparency and traceability in the supply chain, ensuring that components are sourced ethically and sustainably.

C. The Role of Data Analytics in Decision-Making

Data analytics can provide insights into market trends, supplier performance, and inventory levels, enabling more informed procurement decisions.

D. Emphasis on Sustainability and Ethical Sourcing

As sustainability becomes a priority, companies will increasingly focus on ethical sourcing practices and the environmental impact of their procurement decisions.

VIII. Conclusion

The landscape of ceramic capacitor procurement is evolving rapidly, driven by technological advancements, changing market dynamics, and a growing emphasis on sustainability. Understanding the latest trends in ceramic capacitors and the procurement models that support them is essential for companies looking to remain competitive in the electronics industry. By adapting to new models and technologies, businesses can enhance their procurement strategies, ensuring they meet the demands of modern electronics while maintaining quality and reliability.

IX. References

1. Academic journals and articles on ceramic capacitors and procurement strategies.

2. Industry reports and white papers from leading electronics organizations.

3. Manufacturer and supplier websites for the latest product offerings and specifications.

This comprehensive exploration of ceramic capacitors and procurement models highlights the importance of staying informed and adaptable in a rapidly changing industry.

What are the Latest Ceramic Capacitors and Equipment Components Procurement Models?

I. Introduction

Ceramic capacitors are essential components in modern electronics, playing a critical role in various applications ranging from consumer electronics to automotive systems. These passive components store and release electrical energy, helping to stabilize voltage and power flow in circuits. As technology advances, the procurement models for these components are also evolving, reflecting changes in manufacturing processes, supply chain dynamics, and market demands. This blog post explores the latest trends in ceramic capacitors and the procurement models that are shaping the electronics industry.

II. Understanding Ceramic Capacitors

A. Types of Ceramic Capacitors

Ceramic capacitors are primarily categorized into two classes: Class 1 and Class 2 capacitors.

1. **Class 1 Capacitors**: These capacitors are known for their stability and low loss characteristics. They are typically used in applications requiring precise capacitance values, such as timing circuits and filters. The most common dielectric material used in Class 1 capacitors is NP0 (C0G), which offers excellent temperature stability.

2. **Class 2 Capacitors**: In contrast, Class 2 capacitors, such as X7R and Y5V, are designed for higher capacitance values but come with greater variations in capacitance with temperature and voltage. These capacitors are widely used in applications where size and capacitance are more critical than precision, such as decoupling and bypassing in power supply circuits.

B. Key Characteristics and Specifications

When selecting ceramic capacitors, several key characteristics must be considered:

1. **Capacitance Values**: Ceramic capacitors are available in a wide range of capacitance values, from picofarads (pF) to microfarads (µF), allowing for flexibility in design.

2. **Voltage Ratings**: The voltage rating indicates the maximum voltage the capacitor can handle without breaking down. It is crucial to select a capacitor with a voltage rating higher than the maximum voltage in the application.

3. **Temperature Coefficients**: The temperature coefficient affects how capacitance changes with temperature. Understanding these coefficients is vital for applications that operate in varying thermal environments.

C. Applications of Ceramic Capacitors

Ceramic capacitors find applications across various sectors:

1. **Consumer Electronics**: In devices like smartphones, tablets, and laptops, ceramic capacitors are used for decoupling, filtering, and energy storage.

2. **Automotive**: With the rise of electric vehicles and advanced driver-assistance systems (ADAS), ceramic capacitors are crucial for power management and signal processing.

3. **Industrial Applications**: In industrial machinery and automation, these capacitors help in power supply stabilization and noise reduction.

III. Trends in Ceramic Capacitor Technology

A. Advancements in Materials and Manufacturing Processes

Recent advancements in materials science have led to the development of high-k dielectrics, which allow for higher capacitance in smaller packages. This miniaturization trend is essential for meeting the demands of compact electronic devices.

B. Impact of Technology on Performance and Reliability

The integration of advanced manufacturing techniques, such as multilayer ceramic capacitors (MLCCs), has significantly improved the performance and reliability of ceramic capacitors. These capacitors can achieve higher capacitance values while maintaining low equivalent series resistance (ESR), which is critical for high-frequency applications.

C. Sustainability and Eco-Friendly Materials

As the electronics industry moves towards sustainability, manufacturers are exploring eco-friendly materials and processes. This shift not only addresses environmental concerns but also meets the growing demand for sustainable products from consumers and regulatory bodies.

IV. Procurement Models for Ceramic Capacitors

A. Traditional Procurement Models

1. **Direct Purchasing**: This model involves purchasing components directly from manufacturers or distributors. It is straightforward but may not always provide the best pricing or availability.

2. **Bulk Buying**: Companies often purchase large quantities of ceramic capacitors to benefit from volume discounts. However, this approach requires careful inventory management to avoid excess stock.

B. Modern Procurement Strategies

1. **Just-in-Time (JIT) Procurement**: JIT procurement minimizes inventory costs by ordering components only as needed. This model requires strong supplier relationships and reliable logistics.

2. **Vendor-Managed Inventory (VMI)**: In VMI, suppliers manage the inventory levels of their products at the buyer's location. This approach can enhance efficiency and reduce stockouts.

3. **E-Procurement Platforms**: The rise of digital platforms has transformed procurement processes, allowing companies to streamline purchasing, compare prices, and manage suppliers more effectively.

C. Collaborative Procurement Models

1. **Group Purchasing Organizations (GPOs)**: GPOs enable companies to pool their purchasing power to negotiate better prices and terms with suppliers.

2. **Strategic Partnerships with Suppliers**: Building long-term relationships with key suppliers can lead to improved pricing, reliability, and innovation in product offerings.

V. Factors Influencing Procurement Decisions

Several factors influence procurement decisions for ceramic capacitors:

A. Cost Considerations

Cost remains a primary factor in procurement decisions. Companies must balance the need for quality with budget constraints, often leading to negotiations with suppliers.

B. Quality and Reliability

The reliability of ceramic capacitors is paramount, especially in critical applications. Companies must assess supplier quality certifications and track records to ensure they are sourcing reliable components.

C. Lead Times and Supply Chain Dynamics

Lead times can significantly impact production schedules. Companies must consider the reliability of suppliers and their ability to meet demand fluctuations.

D. Supplier Relationships and Performance Metrics

Establishing strong relationships with suppliers can lead to better service and support. Companies often use performance metrics to evaluate supplier reliability, quality, and responsiveness.

VI. Challenges in Ceramic Capacitor Procurement

A. Supply Chain Disruptions

Recent global events have highlighted vulnerabilities in supply chains, leading to delays and shortages of critical components, including ceramic capacitors.

B. Fluctuating Raw Material Prices

The prices of raw materials used in ceramic capacitors can be volatile, impacting overall costs and procurement strategies.

C. Regulatory Compliance and Standards

Compliance with industry standards and regulations is essential for ensuring product safety and reliability. Companies must stay informed about changing regulations that may affect their procurement processes.

D. Technological Obsolescence

As technology evolves, older capacitor models may become obsolete, necessitating continuous monitoring of market trends and innovations.

VII. Future Directions in Procurement Models

A. Integration of AI and Machine Learning in Procurement

Artificial intelligence (AI) and machine learning are poised to revolutionize procurement by enabling predictive analytics, optimizing inventory management, and enhancing supplier selection processes.

B. Blockchain Technology for Transparency and Traceability

Blockchain technology can improve transparency and traceability in the supply chain, ensuring that components are sourced ethically and sustainably.

C. The Role of Data Analytics in Decision-Making

Data analytics can provide insights into market trends, supplier performance, and inventory levels, enabling more informed procurement decisions.

D. Emphasis on Sustainability and Ethical Sourcing

As sustainability becomes a priority, companies will increasingly focus on ethical sourcing practices and the environmental impact of their procurement decisions.

VIII. Conclusion

The landscape of ceramic capacitor procurement is evolving rapidly, driven by technological advancements, changing market dynamics, and a growing emphasis on sustainability. Understanding the latest trends in ceramic capacitors and the procurement models that support them is essential for companies looking to remain competitive in the electronics industry. By adapting to new models and technologies, businesses can enhance their procurement strategies, ensuring they meet the demands of modern electronics while maintaining quality and reliability.

IX. References

1. Academic journals and articles on ceramic capacitors and procurement strategies.

2. Industry reports and white papers from leading electronics organizations.

3. Manufacturer and supplier websites for the latest product offerings and specifications.

This comprehensive exploration of ceramic capacitors and procurement models highlights the importance of staying informed and adaptable in a rapidly changing industry.