Mainstream Models of Capacitor Manufacturers

I. Introduction

Capacitors are fundamental components in electronic circuits, serving as energy storage devices that can release energy when needed. They play a crucial role in various applications, from power supply smoothing to signal coupling and decoupling. The capacitor manufacturing industry has evolved significantly over the years, driven by advancements in technology and increasing demand for electronic devices. This blog post will explore the different types of capacitors, highlight major manufacturers in the industry, and discuss emerging trends that are shaping the future of capacitor production.

II. Types of Capacitors

Capacitors come in various types, each with unique characteristics and applications. Understanding these types is essential for selecting the right capacitor for specific electronic needs.

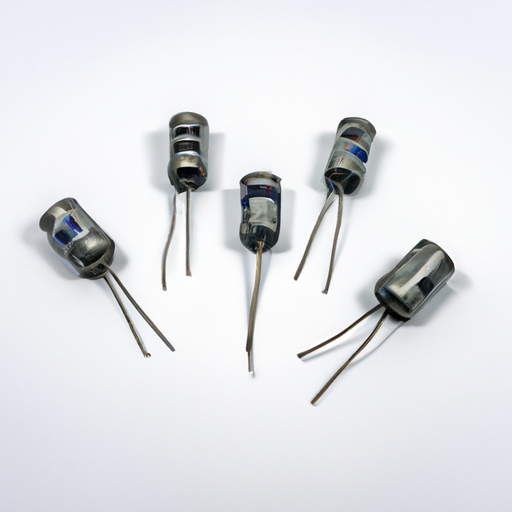

A. Electrolytic Capacitors

Electrolytic capacitors are polarized capacitors that typically have a high capacitance value. They are characterized by their ability to store large amounts of energy in a relatively small volume. Commonly used in power supply circuits, audio equipment, and signal processing, electrolytic capacitors are essential for filtering and smoothing voltage fluctuations.

B. Ceramic Capacitors

Ceramic capacitors are non-polarized capacitors made from ceramic materials. They are known for their stability, reliability, and low cost. These capacitors are widely used in high-frequency applications, such as RF circuits, and are often found in decoupling and bypass applications due to their low equivalent series resistance (ESR).

C. Film Capacitors

Film capacitors are made from thin plastic films and are known for their excellent electrical properties and stability. They are non-polarized and can handle high voltages, making them suitable for applications in power electronics, audio equipment, and timing circuits. Film capacitors are also favored for their long lifespan and low self-inductance.

D. Tantalum Capacitors

Tantalum capacitors are another type of electrolytic capacitor, but they use tantalum metal as the anode. They are known for their high capacitance-to-volume ratio and reliability. Tantalum capacitors are commonly used in applications where space is limited, such as in mobile devices and compact electronic circuits.

E. Supercapacitors

Supercapacitors, also known as ultracapacitors, are energy storage devices that bridge the gap between traditional capacitors and batteries. They can store a significant amount of energy and deliver it quickly, making them ideal for applications requiring rapid charge and discharge cycles, such as in regenerative braking systems and energy harvesting.

III. Major Capacitor Manufacturers

The capacitor manufacturing industry is home to several key players, each contributing to the market with their unique products and technologies. Here, we will explore some of the major capacitor manufacturers.

A. Murata Manufacturing Co., Ltd.

Murata Manufacturing, based in Japan, is a leading manufacturer of ceramic capacitors. The company is known for its innovative technologies and high-quality products. Murata's capacitors are widely used in consumer electronics, automotive applications, and telecommunications. With a strong focus on research and development, Murata maintains a competitive edge in the market.

B. Nichicon Corporation

Nichicon Corporation, also from Japan, specializes in electrolytic capacitors and has a diverse product range that includes aluminum electrolytic capacitors and tantalum capacitors. The company is recognized for its commitment to quality and environmental sustainability. Nichicon's products are commonly used in power supply circuits, audio equipment, and industrial applications.

C. KEMET Corporation

KEMET Corporation, headquartered in the United States, is a prominent manufacturer of capacitors, including ceramic, tantalum, and film capacitors. KEMET is known for its extensive product portfolio and innovative solutions tailored to various industries, including automotive, aerospace, and consumer electronics. The company emphasizes sustainability and has made significant strides in eco-friendly manufacturing practices.

D. Panasonic Corporation

Panasonic Corporation is a global leader in electronics and offers a wide range of capacitors, including aluminum electrolytic, film, and ceramic capacitors. With a strong emphasis on research and development, Panasonic continuously innovates its product offerings to meet the evolving needs of the market. The company's capacitors are widely used in consumer electronics, automotive, and industrial applications.

E. Vishay Intertechnology, Inc.

Vishay Intertechnology is a major player in the capacitor market, providing a diverse range of capacitors, including tantalum, ceramic, and film capacitors. The company is known for its high-quality products and commitment to customer satisfaction. Vishay's capacitors are utilized in various applications, from telecommunications to automotive and industrial sectors.

F. AVX Corporation

AVX Corporation, a subsidiary of Kyocera Corporation, specializes in passive electronic components, including capacitors. The company offers a wide range of capacitors, including ceramic, tantalum, and film types. AVX is recognized for its innovative technologies and high-performance products, catering to industries such as automotive, telecommunications, and consumer electronics.

G. Rubycon Corporation

Rubycon Corporation is a Japanese manufacturer known for its high-quality electrolytic capacitors. The company has a strong reputation for reliability and performance, making its products popular in various applications, including power supplies and audio equipment. Rubycon is committed to sustainability and has implemented eco-friendly practices in its manufacturing processes.

H. WIMA GmbH

WIMA GmbH, based in Germany, specializes in film capacitors and is known for its high-quality products and innovative solutions. The company offers a wide range of capacitors for various applications, including audio, automotive, and industrial sectors. WIMA's commitment to quality and customer service has established it as a trusted name in the capacitor industry.

IV. Emerging Trends in Capacitor Manufacturing

The capacitor manufacturing industry is experiencing several emerging trends that are shaping its future. These trends include technological advancements, sustainability practices, changing market demands, and the impact of global supply chain dynamics.

A. Technological Advancements

Advancements in materials and manufacturing processes are driving innovation in capacitor technology. Manufacturers are exploring new materials, such as graphene and organic compounds, to enhance capacitor performance and efficiency. Additionally, the development of smaller and more efficient capacitors is enabling the miniaturization of electronic devices.

B. Sustainability and Eco-Friendly Practices

As environmental concerns grow, capacitor manufacturers are increasingly adopting sustainable practices. This includes using eco-friendly materials, reducing waste in production processes, and implementing recycling programs. Companies that prioritize sustainability are likely to gain a competitive advantage in the market.

C. Market Demand and Consumer Preferences

The demand for capacitors is closely tied to the growth of various industries, including consumer electronics, automotive, and renewable energy. As consumers seek more efficient and reliable electronic devices, manufacturers must adapt to changing preferences and invest in research and development to meet these demands.

D. Impact of Global Supply Chain Dynamics

The global supply chain has been significantly impacted by recent events, including the COVID-19 pandemic and geopolitical tensions. Capacitor manufacturers must navigate these challenges to ensure a steady supply of raw materials and components. Companies that can adapt to supply chain disruptions will be better positioned to succeed in the competitive market.

V. Conclusion

In summary, capacitors are essential components in electronic circuits, and understanding the different types and their applications is crucial for selecting the right component for specific needs. The capacitor manufacturing industry is home to several major players, each contributing to the market with innovative products and technologies. As the industry evolves, emerging trends such as technological advancements, sustainability practices, and changing market demands will shape the future of capacitor manufacturing. Choosing the right capacitor is vital for ensuring the performance and reliability of electronic devices, making it essential for engineers and designers to stay informed about the latest developments in the industry.

VI. References

1. Academic journals on capacitor technology and applications.

2. Industry reports on the capacitor market and trends.

3. Manufacturer websites for product specifications and innovations.

4. Technical articles and white papers discussing advancements in capacitor technology.

This comprehensive overview of mainstream capacitor manufacturers and their products provides valuable insights for anyone interested in the capacitor industry, whether for academic, professional, or personal purposes.

Mainstream Models of Capacitor Manufacturers

I. Introduction

Capacitors are fundamental components in electronic circuits, serving as energy storage devices that can release energy when needed. They play a crucial role in various applications, from power supply smoothing to signal coupling and decoupling. The capacitor manufacturing industry has evolved significantly over the years, driven by advancements in technology and increasing demand for electronic devices. This blog post will explore the different types of capacitors, highlight major manufacturers in the industry, and discuss emerging trends that are shaping the future of capacitor production.

II. Types of Capacitors

Capacitors come in various types, each with unique characteristics and applications. Understanding these types is essential for selecting the right capacitor for specific electronic needs.

A. Electrolytic Capacitors

Electrolytic capacitors are polarized capacitors that typically have a high capacitance value. They are characterized by their ability to store large amounts of energy in a relatively small volume. Commonly used in power supply circuits, audio equipment, and signal processing, electrolytic capacitors are essential for filtering and smoothing voltage fluctuations.

B. Ceramic Capacitors

Ceramic capacitors are non-polarized capacitors made from ceramic materials. They are known for their stability, reliability, and low cost. These capacitors are widely used in high-frequency applications, such as RF circuits, and are often found in decoupling and bypass applications due to their low equivalent series resistance (ESR).

C. Film Capacitors

Film capacitors are made from thin plastic films and are known for their excellent electrical properties and stability. They are non-polarized and can handle high voltages, making them suitable for applications in power electronics, audio equipment, and timing circuits. Film capacitors are also favored for their long lifespan and low self-inductance.

D. Tantalum Capacitors

Tantalum capacitors are another type of electrolytic capacitor, but they use tantalum metal as the anode. They are known for their high capacitance-to-volume ratio and reliability. Tantalum capacitors are commonly used in applications where space is limited, such as in mobile devices and compact electronic circuits.

E. Supercapacitors

Supercapacitors, also known as ultracapacitors, are energy storage devices that bridge the gap between traditional capacitors and batteries. They can store a significant amount of energy and deliver it quickly, making them ideal for applications requiring rapid charge and discharge cycles, such as in regenerative braking systems and energy harvesting.

III. Major Capacitor Manufacturers

The capacitor manufacturing industry is home to several key players, each contributing to the market with their unique products and technologies. Here, we will explore some of the major capacitor manufacturers.

A. Murata Manufacturing Co., Ltd.

Murata Manufacturing, based in Japan, is a leading manufacturer of ceramic capacitors. The company is known for its innovative technologies and high-quality products. Murata's capacitors are widely used in consumer electronics, automotive applications, and telecommunications. With a strong focus on research and development, Murata maintains a competitive edge in the market.

B. Nichicon Corporation

Nichicon Corporation, also from Japan, specializes in electrolytic capacitors and has a diverse product range that includes aluminum electrolytic capacitors and tantalum capacitors. The company is recognized for its commitment to quality and environmental sustainability. Nichicon's products are commonly used in power supply circuits, audio equipment, and industrial applications.

C. KEMET Corporation

KEMET Corporation, headquartered in the United States, is a prominent manufacturer of capacitors, including ceramic, tantalum, and film capacitors. KEMET is known for its extensive product portfolio and innovative solutions tailored to various industries, including automotive, aerospace, and consumer electronics. The company emphasizes sustainability and has made significant strides in eco-friendly manufacturing practices.

D. Panasonic Corporation

Panasonic Corporation is a global leader in electronics and offers a wide range of capacitors, including aluminum electrolytic, film, and ceramic capacitors. With a strong emphasis on research and development, Panasonic continuously innovates its product offerings to meet the evolving needs of the market. The company's capacitors are widely used in consumer electronics, automotive, and industrial applications.

E. Vishay Intertechnology, Inc.

Vishay Intertechnology is a major player in the capacitor market, providing a diverse range of capacitors, including tantalum, ceramic, and film capacitors. The company is known for its high-quality products and commitment to customer satisfaction. Vishay's capacitors are utilized in various applications, from telecommunications to automotive and industrial sectors.

F. AVX Corporation

AVX Corporation, a subsidiary of Kyocera Corporation, specializes in passive electronic components, including capacitors. The company offers a wide range of capacitors, including ceramic, tantalum, and film types. AVX is recognized for its innovative technologies and high-performance products, catering to industries such as automotive, telecommunications, and consumer electronics.

G. Rubycon Corporation

Rubycon Corporation is a Japanese manufacturer known for its high-quality electrolytic capacitors. The company has a strong reputation for reliability and performance, making its products popular in various applications, including power supplies and audio equipment. Rubycon is committed to sustainability and has implemented eco-friendly practices in its manufacturing processes.

H. WIMA GmbH

WIMA GmbH, based in Germany, specializes in film capacitors and is known for its high-quality products and innovative solutions. The company offers a wide range of capacitors for various applications, including audio, automotive, and industrial sectors. WIMA's commitment to quality and customer service has established it as a trusted name in the capacitor industry.

IV. Emerging Trends in Capacitor Manufacturing

The capacitor manufacturing industry is experiencing several emerging trends that are shaping its future. These trends include technological advancements, sustainability practices, changing market demands, and the impact of global supply chain dynamics.

A. Technological Advancements

Advancements in materials and manufacturing processes are driving innovation in capacitor technology. Manufacturers are exploring new materials, such as graphene and organic compounds, to enhance capacitor performance and efficiency. Additionally, the development of smaller and more efficient capacitors is enabling the miniaturization of electronic devices.

B. Sustainability and Eco-Friendly Practices

As environmental concerns grow, capacitor manufacturers are increasingly adopting sustainable practices. This includes using eco-friendly materials, reducing waste in production processes, and implementing recycling programs. Companies that prioritize sustainability are likely to gain a competitive advantage in the market.

C. Market Demand and Consumer Preferences

The demand for capacitors is closely tied to the growth of various industries, including consumer electronics, automotive, and renewable energy. As consumers seek more efficient and reliable electronic devices, manufacturers must adapt to changing preferences and invest in research and development to meet these demands.

D. Impact of Global Supply Chain Dynamics

The global supply chain has been significantly impacted by recent events, including the COVID-19 pandemic and geopolitical tensions. Capacitor manufacturers must navigate these challenges to ensure a steady supply of raw materials and components. Companies that can adapt to supply chain disruptions will be better positioned to succeed in the competitive market.

V. Conclusion

In summary, capacitors are essential components in electronic circuits, and understanding the different types and their applications is crucial for selecting the right component for specific needs. The capacitor manufacturing industry is home to several major players, each contributing to the market with innovative products and technologies. As the industry evolves, emerging trends such as technological advancements, sustainability practices, and changing market demands will shape the future of capacitor manufacturing. Choosing the right capacitor is vital for ensuring the performance and reliability of electronic devices, making it essential for engineers and designers to stay informed about the latest developments in the industry.

VI. References

1. Academic journals on capacitor technology and applications.

2. Industry reports on the capacitor market and trends.

3. Manufacturer websites for product specifications and innovations.

4. Technical articles and white papers discussing advancements in capacitor technology.

This comprehensive overview of mainstream capacitor manufacturers and their products provides valuable insights for anyone interested in the capacitor industry, whether for academic, professional, or personal purposes.