Development Trends in the Fixed Resistor Industry

I. Introduction

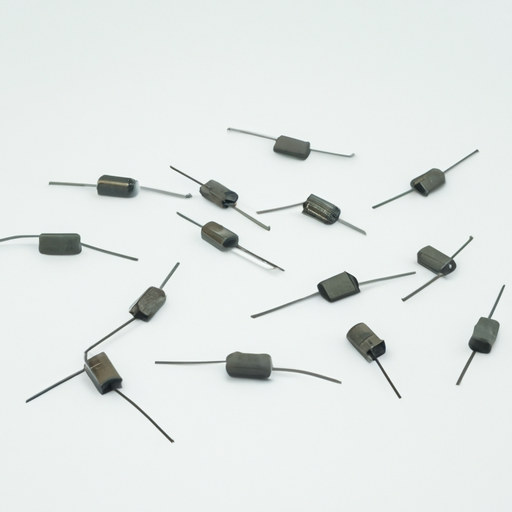

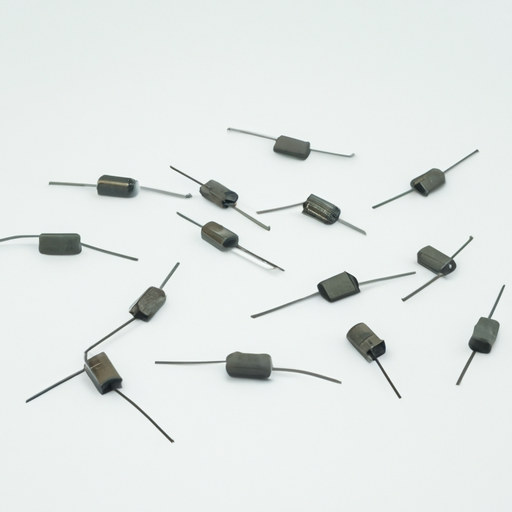

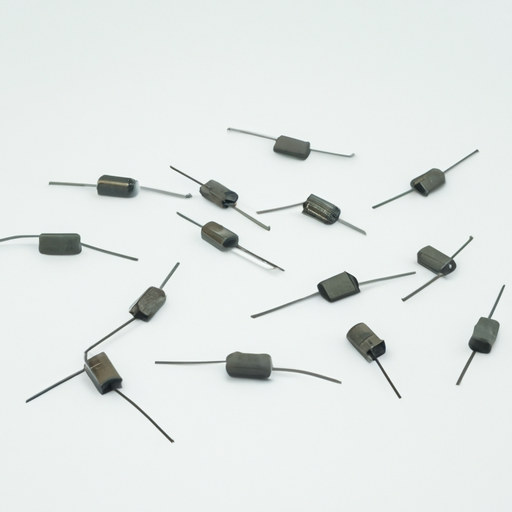

Fixed resistors are fundamental components in electronic circuits, serving the essential function of limiting current flow and dividing voltages. Their importance cannot be overstated, as they are integral to the operation of virtually all electronic devices, from simple household appliances to complex industrial machinery. The fixed resistor industry has evolved significantly over the years, adapting to technological advancements and changing market demands. This blog post explores the development trends in the fixed resistor industry, highlighting historical context, current market dynamics, technological innovations, sustainability considerations, and future outlooks.

II. Historical Context

The evolution of fixed resistors dates back to the early days of electronics. Initially, resistors were made from simple materials like carbon and wire. The introduction of carbon film and metal film resistors marked a significant milestone, offering improved performance and reliability. Traditional manufacturing processes involved manual assembly and basic materials, which limited precision and scalability.

As technology progressed, the fixed resistor industry saw the advent of automated manufacturing processes, allowing for greater consistency and efficiency. The development of surface mount technology (SMT) in the late 20th century further revolutionized the industry, enabling the production of smaller, more efficient components that could be easily integrated into modern electronic devices.

III. Current Market Landscape

Today, the global fixed resistor market is robust and diverse, with a market size that continues to grow. According to recent market analyses, the fixed resistor industry is projected to expand at a compound annual growth rate (CAGR) of approximately 5% over the next few years. Key players in the market include established manufacturers such as Vishay Intertechnology, Yageo Corporation, and Panasonic, among others.

Fixed resistors find applications across various industries, including consumer electronics, automotive, telecommunications, and industrial applications. In consumer electronics, they are used in devices like smartphones, televisions, and computers. In the automotive sector, fixed resistors play a crucial role in electronic control units (ECUs) and safety systems. Telecommunications rely on fixed resistors for signal processing and transmission, while industrial applications utilize them in automation and control systems.

IV. Technological Advancements

A. Innovations in Materials

The materials used in fixed resistor manufacturing have evolved significantly. Carbon film resistors, once the standard, are increasingly being replaced by metal film resistors, which offer superior performance in terms of stability and accuracy. Additionally, the use of nanotechnology in resistor manufacturing is gaining traction, allowing for the creation of resistors with enhanced properties, such as improved temperature stability and lower noise levels.

B. Miniaturization and Surface Mount Technology (SMT)

The trend towards miniaturization has been a defining characteristic of the electronics industry, and fixed resistors are no exception. The shift to surface mount technology (SMT) has enabled the production of smaller components that occupy less space on circuit boards. This miniaturization not only allows for more compact designs but also enhances circuit performance by reducing parasitic effects.

C. Enhanced Precision and Reliability

As electronic devices become more sophisticated, the demand for high-precision resistors has increased. Manufacturers are responding by developing resistors with tighter tolerances and improved temperature stability. These advancements ensure that fixed resistors can perform reliably in a wide range of operating conditions, making them suitable for critical applications in aerospace, medical devices, and high-frequency circuits.

V. Sustainability and Environmental Considerations

In recent years, there has been a growing emphasis on sustainability within the fixed resistor industry. Manufacturers are increasingly shifting towards eco-friendly materials and production processes. This includes the use of lead-free solder and recyclable materials, which help reduce the environmental impact of resistor production.

Recycling and waste management are also becoming important considerations. Many manufacturers are implementing programs to recycle old components and minimize waste generated during production. Additionally, regulatory pressures are prompting companies to comply with environmental standards, such as the Restriction of Hazardous Substances (RoHS) directive, which restricts the use of certain hazardous materials in electronic products.

VI. Market Trends and Consumer Demands

The fixed resistor market is witnessing several key trends driven by consumer demands. One notable trend is the increasing demand for high-performance resistors. As electronic devices become more advanced, there is a growing need for resistors that can handle higher power levels and provide greater accuracy.

Customization is another significant trend, with manufacturers offering application-specific solutions tailored to meet the unique requirements of various industries. This trend is particularly evident in sectors like automotive and telecommunications, where specialized resistors are needed for specific applications.

The rise of smart technologies, including the Internet of Things (IoT) and smart home devices, is also impacting resistor design. These technologies require components that can operate efficiently in connected environments, leading to innovations in resistor technology that enhance performance and reliability.

VII. Challenges Facing the Fixed Resistor Industry

Despite the positive trends, the fixed resistor industry faces several challenges. Supply chain disruptions and material shortages have become increasingly common, particularly in the wake of global events such as the COVID-19 pandemic. These disruptions can lead to delays in production and increased costs for manufacturers.

Competition from alternative technologies, such as digital resistors and programmable devices, poses another challenge. As these technologies gain traction, traditional fixed resistors may face pressure to innovate and adapt to changing market demands.

Balancing cost and performance is an ongoing challenge for manufacturers. While there is a demand for high-performance resistors, cost considerations remain critical, particularly in price-sensitive markets. Manufacturers must find ways to enhance performance without significantly increasing production costs.

VIII. Future Outlook

Looking ahead, the fixed resistor market is poised for continued growth. Predictions indicate that the demand for fixed resistors will remain strong, driven by advancements in technology and the increasing complexity of electronic devices. Emerging technologies, such as artificial intelligence and machine learning, are expected to create new opportunities for fixed resistor applications.

Manufacturers are encouraged to invest in research and development to stay ahead of the curve. Innovations in materials, production processes, and design will be crucial for meeting the evolving needs of the market. Additionally, strategic partnerships and collaborations can help manufacturers leverage new technologies and expand their product offerings.

IX. Conclusion

In summary, the fixed resistor industry is undergoing significant transformations driven by technological advancements, market demands, and sustainability considerations. The evolution of materials, miniaturization, and the push for high-performance components are shaping the future of fixed resistors. As the industry navigates challenges such as supply chain disruptions and competition from alternative technologies, innovation will be key to maintaining relevance in the ever-evolving electronics landscape. The future of fixed resistors is bright, with opportunities for growth and development in a wide range of applications.

X. References

1. Academic journals and articles on resistor technology and market trends.

2. Industry reports and market analyses from reputable sources.

3. Manufacturer publications and white papers detailing advancements in fixed resistor technology.

This blog post provides a comprehensive overview of the development trends in the fixed resistor industry, highlighting the importance of innovation and adaptation in a rapidly changing market.

Development Trends in the Fixed Resistor Industry

I. Introduction

Fixed resistors are fundamental components in electronic circuits, serving the essential function of limiting current flow and dividing voltages. Their importance cannot be overstated, as they are integral to the operation of virtually all electronic devices, from simple household appliances to complex industrial machinery. The fixed resistor industry has evolved significantly over the years, adapting to technological advancements and changing market demands. This blog post explores the development trends in the fixed resistor industry, highlighting historical context, current market dynamics, technological innovations, sustainability considerations, and future outlooks.

II. Historical Context

The evolution of fixed resistors dates back to the early days of electronics. Initially, resistors were made from simple materials like carbon and wire. The introduction of carbon film and metal film resistors marked a significant milestone, offering improved performance and reliability. Traditional manufacturing processes involved manual assembly and basic materials, which limited precision and scalability.

As technology progressed, the fixed resistor industry saw the advent of automated manufacturing processes, allowing for greater consistency and efficiency. The development of surface mount technology (SMT) in the late 20th century further revolutionized the industry, enabling the production of smaller, more efficient components that could be easily integrated into modern electronic devices.

III. Current Market Landscape

Today, the global fixed resistor market is robust and diverse, with a market size that continues to grow. According to recent market analyses, the fixed resistor industry is projected to expand at a compound annual growth rate (CAGR) of approximately 5% over the next few years. Key players in the market include established manufacturers such as Vishay Intertechnology, Yageo Corporation, and Panasonic, among others.

Fixed resistors find applications across various industries, including consumer electronics, automotive, telecommunications, and industrial applications. In consumer electronics, they are used in devices like smartphones, televisions, and computers. In the automotive sector, fixed resistors play a crucial role in electronic control units (ECUs) and safety systems. Telecommunications rely on fixed resistors for signal processing and transmission, while industrial applications utilize them in automation and control systems.

IV. Technological Advancements

A. Innovations in Materials

The materials used in fixed resistor manufacturing have evolved significantly. Carbon film resistors, once the standard, are increasingly being replaced by metal film resistors, which offer superior performance in terms of stability and accuracy. Additionally, the use of nanotechnology in resistor manufacturing is gaining traction, allowing for the creation of resistors with enhanced properties, such as improved temperature stability and lower noise levels.

B. Miniaturization and Surface Mount Technology (SMT)

The trend towards miniaturization has been a defining characteristic of the electronics industry, and fixed resistors are no exception. The shift to surface mount technology (SMT) has enabled the production of smaller components that occupy less space on circuit boards. This miniaturization not only allows for more compact designs but also enhances circuit performance by reducing parasitic effects.

C. Enhanced Precision and Reliability

As electronic devices become more sophisticated, the demand for high-precision resistors has increased. Manufacturers are responding by developing resistors with tighter tolerances and improved temperature stability. These advancements ensure that fixed resistors can perform reliably in a wide range of operating conditions, making them suitable for critical applications in aerospace, medical devices, and high-frequency circuits.

V. Sustainability and Environmental Considerations

In recent years, there has been a growing emphasis on sustainability within the fixed resistor industry. Manufacturers are increasingly shifting towards eco-friendly materials and production processes. This includes the use of lead-free solder and recyclable materials, which help reduce the environmental impact of resistor production.

Recycling and waste management are also becoming important considerations. Many manufacturers are implementing programs to recycle old components and minimize waste generated during production. Additionally, regulatory pressures are prompting companies to comply with environmental standards, such as the Restriction of Hazardous Substances (RoHS) directive, which restricts the use of certain hazardous materials in electronic products.

VI. Market Trends and Consumer Demands

The fixed resistor market is witnessing several key trends driven by consumer demands. One notable trend is the increasing demand for high-performance resistors. As electronic devices become more advanced, there is a growing need for resistors that can handle higher power levels and provide greater accuracy.

Customization is another significant trend, with manufacturers offering application-specific solutions tailored to meet the unique requirements of various industries. This trend is particularly evident in sectors like automotive and telecommunications, where specialized resistors are needed for specific applications.

The rise of smart technologies, including the Internet of Things (IoT) and smart home devices, is also impacting resistor design. These technologies require components that can operate efficiently in connected environments, leading to innovations in resistor technology that enhance performance and reliability.

VII. Challenges Facing the Fixed Resistor Industry

Despite the positive trends, the fixed resistor industry faces several challenges. Supply chain disruptions and material shortages have become increasingly common, particularly in the wake of global events such as the COVID-19 pandemic. These disruptions can lead to delays in production and increased costs for manufacturers.

Competition from alternative technologies, such as digital resistors and programmable devices, poses another challenge. As these technologies gain traction, traditional fixed resistors may face pressure to innovate and adapt to changing market demands.

Balancing cost and performance is an ongoing challenge for manufacturers. While there is a demand for high-performance resistors, cost considerations remain critical, particularly in price-sensitive markets. Manufacturers must find ways to enhance performance without significantly increasing production costs.

VIII. Future Outlook

Looking ahead, the fixed resistor market is poised for continued growth. Predictions indicate that the demand for fixed resistors will remain strong, driven by advancements in technology and the increasing complexity of electronic devices. Emerging technologies, such as artificial intelligence and machine learning, are expected to create new opportunities for fixed resistor applications.

Manufacturers are encouraged to invest in research and development to stay ahead of the curve. Innovations in materials, production processes, and design will be crucial for meeting the evolving needs of the market. Additionally, strategic partnerships and collaborations can help manufacturers leverage new technologies and expand their product offerings.

IX. Conclusion

In summary, the fixed resistor industry is undergoing significant transformations driven by technological advancements, market demands, and sustainability considerations. The evolution of materials, miniaturization, and the push for high-performance components are shaping the future of fixed resistors. As the industry navigates challenges such as supply chain disruptions and competition from alternative technologies, innovation will be key to maintaining relevance in the ever-evolving electronics landscape. The future of fixed resistors is bright, with opportunities for growth and development in a wide range of applications.

X. References

1. Academic journals and articles on resistor technology and market trends.

2. Industry reports and market analyses from reputable sources.

3. Manufacturer publications and white papers detailing advancements in fixed resistor technology.

This blog post provides a comprehensive overview of the development trends in the fixed resistor industry, highlighting the importance of innovation and adaptation in a rapidly changing market.