What are the Product Features of Chip Resistors?

I. Introduction

A. Definition of Chip Resistors

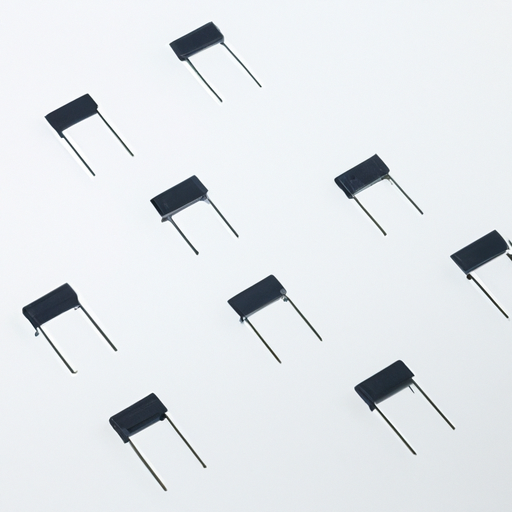

Chip resistors are miniature electronic components that provide resistance in a circuit. Unlike traditional resistors, which often come in larger, cylindrical forms, chip resistors are flat and rectangular, allowing them to be mounted directly onto circuit boards. This compact design is essential for modern electronics, where space is at a premium.

B. Importance of Chip Resistors in Electronic Circuits

Chip resistors play a critical role in controlling current flow, dividing voltages, and protecting sensitive components from excessive current. Their reliability and precision make them indispensable in various applications, from consumer electronics to industrial machinery.

C. Purpose of the Article

This article aims to explore the key product features of chip resistors, providing insights into their design, performance characteristics, and applications. Understanding these features is crucial for engineers and designers when selecting the right resistor for their projects.

II. Overview of Chip Resistors

A. What are Chip Resistors?

1. Description and Structure

Chip resistors are typically made from a resistive material that is deposited onto a ceramic substrate. This construction allows for a high degree of precision in resistance values and ensures stability under varying conditions.

2. Types of Chip Resistors

There are several types of chip resistors, including thin film, thick film, and wire-wound resistors. Thin film resistors offer high precision and stability, while thick film resistors are more common due to their cost-effectiveness and versatility.

B. Common Applications

1. Consumer Electronics

Chip resistors are widely used in smartphones, tablets, and other consumer devices, where their small size and reliability are essential.

2. Automotive Industry

In automotive applications, chip resistors are used in control systems, sensors, and safety features, where precision and durability are critical.

3. Telecommunications

Chip resistors are integral to communication devices, ensuring signal integrity and performance in high-frequency applications.

4. Industrial Equipment

In industrial settings, chip resistors are used in automation systems, robotics, and machinery, where they help manage power and signal processing.

III. Key Product Features of Chip Resistors

A. Resistance Value

1. Range of Resistance Values

Chip resistors are available in a wide range of resistance values, typically from a few ohms to several megaohms. This versatility allows designers to select the appropriate resistor for their specific needs.

2. Tolerance Levels

Tolerance refers to the allowable deviation from the specified resistance value. Chip resistors come with various tolerance levels, commonly ranging from ±1% to ±0.1%, allowing for precise control in circuits.

B. Power Rating

1. Definition and Importance

Power rating indicates the maximum power a resistor can dissipate without overheating. It is crucial for ensuring that the resistor operates safely within its limits.

2. Power Rating Categories

Chip resistors are categorized by their power ratings, which typically range from 1/16 watt to several watts, depending on the application requirements.

C. Temperature Coefficient

1. Explanation of Temperature Coefficient

The temperature coefficient measures how much a resistor's value changes with temperature. A lower temperature coefficient indicates better stability across temperature variations.

2. Impact on Performance

Resistors with a low temperature coefficient are preferred in precision applications, as they maintain consistent performance even in fluctuating environmental conditions.

D. Size and Form Factor

1. Standard Sizes (e.g., 0402, 0603, 0805)

Chip resistors come in standardized sizes, such as 0402 (1.0mm x 0.5mm), 0603 (1.6mm x 0.8mm), and 0805 (2.0mm x 1.25mm). These sizes are designed to fit various circuit board layouts.

2. Importance of Size in Design

The size of a chip resistor affects its power rating, resistance value, and application suitability. Designers must consider size when optimizing circuit layouts for performance and space.

E. Material Composition

1. Common Materials Used (e.g., Thin Film, Thick Film)

Chip resistors are made from different materials, with thin film and thick film being the most common. Thin film resistors offer higher precision, while thick film resistors are more robust and cost-effective.

2. Impact on Performance and Reliability

The choice of material affects the resistor's performance characteristics, including stability, noise, and temperature coefficient. High-quality materials enhance reliability and longevity.

F. Voltage Rating

1. Definition and Importance

Voltage rating indicates the maximum voltage a resistor can handle without breaking down. It is essential for preventing damage in high-voltage applications.

2. Considerations for Voltage Rating

When selecting a chip resistor, designers must consider the operating voltage of the circuit to ensure the resistor can handle the required voltage levels safely.

G. Noise Characteristics

1. Types of Noise in Resistors

Resistors can introduce noise into a circuit, which can affect performance, especially in sensitive applications. Common types of noise include thermal noise and flicker noise.

2. Importance of Low Noise in Applications

Low-noise chip resistors are crucial in audio, RF, and precision measurement applications, where signal integrity is paramount.

H. Reliability and Longevity

1. Factors Affecting Reliability

Factors such as temperature, humidity, and mechanical stress can impact the reliability of chip resistors. Selecting resistors with appropriate ratings for the intended environment is essential.

2. Testing Standards and Certifications

Chip resistors are often tested against industry standards, such as MIL-PRF-55342, to ensure reliability and performance. Certifications provide assurance of quality and longevity.

IV. Performance Characteristics

A. Stability and Drift

1. Definition of Stability

Stability refers to a resistor's ability to maintain its resistance value over time and under varying conditions. High stability is essential for precision applications.

2. Factors Influencing Drift

Drift can be influenced by temperature changes, humidity, and aging. Selecting resistors with low drift characteristics is vital for maintaining circuit performance.

B. Frequency Response

1. Importance in High-Frequency Applications

In high-frequency applications, the frequency response of a resistor can significantly impact circuit performance. Chip resistors must be designed to minimize parasitic effects.

2. Impedance Considerations

Impedance matching is crucial in RF applications. Chip resistors with appropriate impedance characteristics help ensure signal integrity and minimize reflections.

C. Environmental Resistance

1. Moisture and Humidity Resistance

Chip resistors must be resistant to moisture and humidity to prevent degradation and failure in harsh environments. Coatings and encapsulations can enhance moisture resistance.

2. Temperature and Chemical Resistance

Resistors should also withstand temperature fluctuations and exposure to chemicals. Selecting resistors with appropriate ratings ensures reliability in various conditions.

V. Manufacturing Processes

A. Overview of Chip Resistor Manufacturing

The manufacturing process of chip resistors involves several steps, including material selection, deposition, and packaging. Advanced techniques ensure high precision and quality.

B. Quality Control Measures

Quality control is critical in chip resistor manufacturing. Rigorous testing and inspection processes help ensure that resistors meet specified performance standards.

C. Innovations in Manufacturing Technology

Recent advancements in manufacturing technology, such as automation and improved materials, have enhanced the performance and reliability of chip resistors.

VI. Comparison with Other Resistor Types

A. Chip Resistors vs. Through-Hole Resistors

Chip resistors are generally smaller and more suitable for automated assembly compared to through-hole resistors, which are larger and require manual soldering.

B. Advantages and Disadvantages

Chip resistors offer advantages in size, performance, and reliability, while through-hole resistors may be easier to handle and replace in certain applications.

C. When to Use Chip Resistors vs. Other Types

Designers should consider factors such as space, performance requirements, and assembly methods when choosing between chip resistors and other types.

VII. Conclusion

A. Summary of Key Features

Chip resistors are essential components in modern electronics, offering a range of features such as precise resistance values, power ratings, and environmental resistance.

B. Importance of Selecting the Right Chip Resistor

Choosing the right chip resistor is crucial for ensuring circuit performance and reliability. Designers must consider various factors, including resistance value, power rating, and environmental conditions.

C. Future Trends in Chip Resistor Technology

As technology advances, chip resistors will continue to evolve, with trends focusing on miniaturization, improved performance, and enhanced reliability to meet the demands of emerging applications.

VIII. References

A. Academic Journals

- IEEE Transactions on Components, Packaging and Manufacturing Technology

- Journal of Electronic Materials

B. Industry Publications

- Electronic Design Magazine

- EDN Network

C. Manufacturer Specifications and Datasheets

- Vishay Intertechnology

- Yageo Corporation

In conclusion, understanding the product features of chip resistors is vital for anyone involved in electronics design and manufacturing. Their compact size, reliability, and versatility make them a preferred choice in a wide range of applications, from consumer electronics to industrial systems. By considering the key features outlined in this article, designers can make informed decisions that enhance the performance and longevity of their electronic circuits.

What are the Product Features of Chip Resistors?

I. Introduction

A. Definition of Chip Resistors

Chip resistors are miniature electronic components that provide resistance in a circuit. Unlike traditional resistors, which often come in larger, cylindrical forms, chip resistors are flat and rectangular, allowing them to be mounted directly onto circuit boards. This compact design is essential for modern electronics, where space is at a premium.

B. Importance of Chip Resistors in Electronic Circuits

Chip resistors play a critical role in controlling current flow, dividing voltages, and protecting sensitive components from excessive current. Their reliability and precision make them indispensable in various applications, from consumer electronics to industrial machinery.

C. Purpose of the Article

This article aims to explore the key product features of chip resistors, providing insights into their design, performance characteristics, and applications. Understanding these features is crucial for engineers and designers when selecting the right resistor for their projects.

II. Overview of Chip Resistors

A. What are Chip Resistors?

1. Description and Structure

Chip resistors are typically made from a resistive material that is deposited onto a ceramic substrate. This construction allows for a high degree of precision in resistance values and ensures stability under varying conditions.

2. Types of Chip Resistors

There are several types of chip resistors, including thin film, thick film, and wire-wound resistors. Thin film resistors offer high precision and stability, while thick film resistors are more common due to their cost-effectiveness and versatility.

B. Common Applications

1. Consumer Electronics

Chip resistors are widely used in smartphones, tablets, and other consumer devices, where their small size and reliability are essential.

2. Automotive Industry

In automotive applications, chip resistors are used in control systems, sensors, and safety features, where precision and durability are critical.

3. Telecommunications

Chip resistors are integral to communication devices, ensuring signal integrity and performance in high-frequency applications.

4. Industrial Equipment

In industrial settings, chip resistors are used in automation systems, robotics, and machinery, where they help manage power and signal processing.

III. Key Product Features of Chip Resistors

A. Resistance Value

1. Range of Resistance Values

Chip resistors are available in a wide range of resistance values, typically from a few ohms to several megaohms. This versatility allows designers to select the appropriate resistor for their specific needs.

2. Tolerance Levels

Tolerance refers to the allowable deviation from the specified resistance value. Chip resistors come with various tolerance levels, commonly ranging from ±1% to ±0.1%, allowing for precise control in circuits.

B. Power Rating

1. Definition and Importance

Power rating indicates the maximum power a resistor can dissipate without overheating. It is crucial for ensuring that the resistor operates safely within its limits.

2. Power Rating Categories

Chip resistors are categorized by their power ratings, which typically range from 1/16 watt to several watts, depending on the application requirements.

C. Temperature Coefficient

1. Explanation of Temperature Coefficient

The temperature coefficient measures how much a resistor's value changes with temperature. A lower temperature coefficient indicates better stability across temperature variations.

2. Impact on Performance

Resistors with a low temperature coefficient are preferred in precision applications, as they maintain consistent performance even in fluctuating environmental conditions.

D. Size and Form Factor

1. Standard Sizes (e.g., 0402, 0603, 0805)

Chip resistors come in standardized sizes, such as 0402 (1.0mm x 0.5mm), 0603 (1.6mm x 0.8mm), and 0805 (2.0mm x 1.25mm). These sizes are designed to fit various circuit board layouts.

2. Importance of Size in Design

The size of a chip resistor affects its power rating, resistance value, and application suitability. Designers must consider size when optimizing circuit layouts for performance and space.

E. Material Composition

1. Common Materials Used (e.g., Thin Film, Thick Film)

Chip resistors are made from different materials, with thin film and thick film being the most common. Thin film resistors offer higher precision, while thick film resistors are more robust and cost-effective.

2. Impact on Performance and Reliability

The choice of material affects the resistor's performance characteristics, including stability, noise, and temperature coefficient. High-quality materials enhance reliability and longevity.

F. Voltage Rating

1. Definition and Importance

Voltage rating indicates the maximum voltage a resistor can handle without breaking down. It is essential for preventing damage in high-voltage applications.

2. Considerations for Voltage Rating

When selecting a chip resistor, designers must consider the operating voltage of the circuit to ensure the resistor can handle the required voltage levels safely.

G. Noise Characteristics

1. Types of Noise in Resistors

Resistors can introduce noise into a circuit, which can affect performance, especially in sensitive applications. Common types of noise include thermal noise and flicker noise.

2. Importance of Low Noise in Applications

Low-noise chip resistors are crucial in audio, RF, and precision measurement applications, where signal integrity is paramount.

H. Reliability and Longevity

1. Factors Affecting Reliability

Factors such as temperature, humidity, and mechanical stress can impact the reliability of chip resistors. Selecting resistors with appropriate ratings for the intended environment is essential.

2. Testing Standards and Certifications

Chip resistors are often tested against industry standards, such as MIL-PRF-55342, to ensure reliability and performance. Certifications provide assurance of quality and longevity.

IV. Performance Characteristics

A. Stability and Drift

1. Definition of Stability

Stability refers to a resistor's ability to maintain its resistance value over time and under varying conditions. High stability is essential for precision applications.

2. Factors Influencing Drift

Drift can be influenced by temperature changes, humidity, and aging. Selecting resistors with low drift characteristics is vital for maintaining circuit performance.

B. Frequency Response

1. Importance in High-Frequency Applications

In high-frequency applications, the frequency response of a resistor can significantly impact circuit performance. Chip resistors must be designed to minimize parasitic effects.

2. Impedance Considerations

Impedance matching is crucial in RF applications. Chip resistors with appropriate impedance characteristics help ensure signal integrity and minimize reflections.

C. Environmental Resistance

1. Moisture and Humidity Resistance

Chip resistors must be resistant to moisture and humidity to prevent degradation and failure in harsh environments. Coatings and encapsulations can enhance moisture resistance.

2. Temperature and Chemical Resistance

Resistors should also withstand temperature fluctuations and exposure to chemicals. Selecting resistors with appropriate ratings ensures reliability in various conditions.

V. Manufacturing Processes

A. Overview of Chip Resistor Manufacturing

The manufacturing process of chip resistors involves several steps, including material selection, deposition, and packaging. Advanced techniques ensure high precision and quality.

B. Quality Control Measures

Quality control is critical in chip resistor manufacturing. Rigorous testing and inspection processes help ensure that resistors meet specified performance standards.

C. Innovations in Manufacturing Technology

Recent advancements in manufacturing technology, such as automation and improved materials, have enhanced the performance and reliability of chip resistors.

VI. Comparison with Other Resistor Types

A. Chip Resistors vs. Through-Hole Resistors

Chip resistors are generally smaller and more suitable for automated assembly compared to through-hole resistors, which are larger and require manual soldering.

B. Advantages and Disadvantages

Chip resistors offer advantages in size, performance, and reliability, while through-hole resistors may be easier to handle and replace in certain applications.

C. When to Use Chip Resistors vs. Other Types

Designers should consider factors such as space, performance requirements, and assembly methods when choosing between chip resistors and other types.

VII. Conclusion

A. Summary of Key Features

Chip resistors are essential components in modern electronics, offering a range of features such as precise resistance values, power ratings, and environmental resistance.

B. Importance of Selecting the Right Chip Resistor

Choosing the right chip resistor is crucial for ensuring circuit performance and reliability. Designers must consider various factors, including resistance value, power rating, and environmental conditions.

C. Future Trends in Chip Resistor Technology

As technology advances, chip resistors will continue to evolve, with trends focusing on miniaturization, improved performance, and enhanced reliability to meet the demands of emerging applications.

VIII. References

A. Academic Journals

- IEEE Transactions on Components, Packaging and Manufacturing Technology

- Journal of Electronic Materials

B. Industry Publications

- Electronic Design Magazine

- EDN Network

C. Manufacturer Specifications and Datasheets

- Vishay Intertechnology

- Yageo Corporation

In conclusion, understanding the product features of chip resistors is vital for anyone involved in electronics design and manufacturing. Their compact size, reliability, and versatility make them a preferred choice in a wide range of applications, from consumer electronics to industrial systems. By considering the key features outlined in this article, designers can make informed decisions that enhance the performance and longevity of their electronic circuits.